Printing Process

You can also choose different 3D printing colors. Entscheiden Sie selbst, welches sich am besten für Ihr Project einet order welden Sie sich von ours beraten.

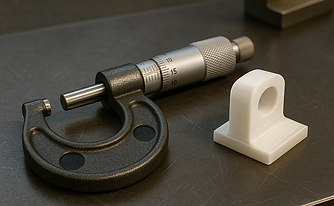

Here's a preview:

SLS

-

To Paint: Selective Laser Sintering (SLS) uses a laser to transform the materials into pieces.

-

Material Failure: Different plastics and materials could be printed.

-

Stability: These affected parts are mechanically highly resilient.

-

Support Structure: There are no structural structures that stabilize the Pulver itself.

Our Fertilization Network

Base3D set up a strong network network partner in Germany and Australia. Our production partner is specialized in manufacturing and manufacturing 3D printing solutions.

Thanks to our international structures and unrestricted development, we realize our projects in a timely manner that will ensure fair market prices. After all, we will take care of your wishes with your order within 24 hours of your life.

Performances

We used modern Technology

Base3D draws on a proven network of local and international manufacturers – all with many years of experience in the precise production of high-quality 3D Printed parts.

We utilize cutting-edge additive manufacturing technologies to create complex geometries, functional prototypes, and series parts of the highest quality. Our scalable production capacities within a globally connected supply chain enable us to bring your designs into production quickly, flexibly, and at highly competitive prices.

Why Base3D

Print quality Standards

At Base3D, we pride ourselves on delivering precise, reliable, and high-quality 3D-printed components. Our mission: To provide innovative manufacturing solutions that set standards in design, functionality, and efficiency.

Fast Production

Whether prototype or series part: We 3D print your components directly. Thanks to our efficient order processing and express options, you often receive your order within 24 to 72 hours – reliably and on time.

Fair Prices

At Base3D, you get high-quality 3D printing solutions at a fair price. No hidden costs – you only pay for what you really need: materials, printing time, and, if desired, additional services such as post-processing or design customization.

Need your parts faster? We're here for you.

Accelerate your project with Base3D's highly efficient digital manufacturing. Thanks to our optimized production process and printer network, we deliver your 3D-printed parts in just 1–3 days, depending on the material and design.

With automated file processing, instant quotations, and professional in-house printing, we're built for speed—without compromising on precision.

Our ordering Process

Insert CAD file

You can securely upload your component design using our online quotation configurator.

Direct Offer

We calculate your costs for the 3D model in real Time.

Production

We select the most suitable producer for your order and start production immediately.

Quality control

We take full responsibility for ensuring that your parts are manufactured according to our standards.

Additional design and application resources for 3D Printing

Introduction Guides

Introduction to 3D printing Techniques

Introductory information about FDM-3D

Introduction to SLA 3D printing Methods

Introduction to 3D printing Processes

Introduction Guides

Essential for 3D printing

How to design components for FDM

Housing design for 3D Printing

Introduction to 3D printing Techniques

Material Guidelines

PLA vs. ABS: What's the difference?

DM 3D printing materials in Comparison

Introduction to 3D printing techniques

SLA 3D printing materials in Comparison

Applications

3D printing for small-series injection molds

3D printing applications for aviation

Medical 3D printing Applications

3D printing applications for the automotive industry

CAD and file Preparation

CAD 3D modeling Software

Simulations for 3D Printing

STL files for 3D printing: step-by-step instructions

Troubleshooting and correcting common STL file errors

Post-processing and finishing

Post-processing of FDM-printed parts

Post-processing of SLA-printed parts

Post-processing of SLS-printed parts